A minimum order quantity (MOQ) may be required when ordering from a particular manufacturer or wholesaler. This means that manufacturers, suppliers, and wholesalers may reject certain customers if they cannot or will not meet the minimum order quantity.

It may seem counterintuitive that rejecting a customer could increase profits, but how minimum order quantity works and some suppliers are particularly low margin or highly profitable orders. It is important to understand what to use for custom orders. With careful management, the minimum order quantity can increase your profit.

DocShipper Info

If you need a quote to calculate the MOQ, or any other details regarding your order or your shipment, Docshipper with its expertise in Sourcing, procurement, freight forwarding and 3PL can assist from A to Z through the whole process …. all you have to do is to contact our experts.

What exactly is the minimum order quantity (MOQ)?

The minimum order quantity is the minimum quantity of parts that a company is ready to make a sale to its customers at one time. Retailers are pleased to vend T-shirts and lettuce heads, but selling units is usually not beneficial. Some products may impose a minimum order quantity of a few hundred or thousands of pieces.

Many manufacturers use MOQ to sell to wholesalers and then to retailers. After that, the individual can go to the warehouse and buy only one or two products.

The Definition of the minimum order quantity

The general definition of minimum order quantity is as follows:

Minimum order quantity is the minimum number of pieces that must be acquired at one time.

In order to better comprehend the meaning of MOQ, here is an example. Suppose a wholesale vendor sells each unit for $100. Sellers have a minimum order quantity of 100 units or at least $10,000 for widgets. The MOQ can be calculated on a per-unit basis or in dollars. In any case, this MOQ is at least the minimum threshold required for a company to make a profit on a specific order. This calculation can include setup costs, management costs, the minimum amount of primary products a supplier can place an order, and other restrictions.

The use of the minimum order quantity (MOQ)

In general, vendors use MOQ for one cause. That reason is sales margin, which is the value of the profit you make selling a service or an article. If a vendor sells a product with a minimal margin or margins, damages can require a significant amount of money, even after taking into account miscellaneous and other regular costs.

The reasons and methods for determining QA vary from industry to industry. For example, a manufacturer that needs to mount a production process may have a large initial cost. If the number of units sold is not sufficient to offset this cost, the effort is not worth it.

The manufacturer or wholesaler wants to sell the case of the product and sell the complete cases to be excluded the extra effort and cost associated with partially disassembling and shipping the product. For example, if you sell shampoo, you ship 12 units of cases, so your MOQ will be 12 per case.

DocShipper Tip

If you have any questions about the MOQ, or any other step of the sourcing or procurement process ,do not hesitate to contact us, Our team will answer within 24h.

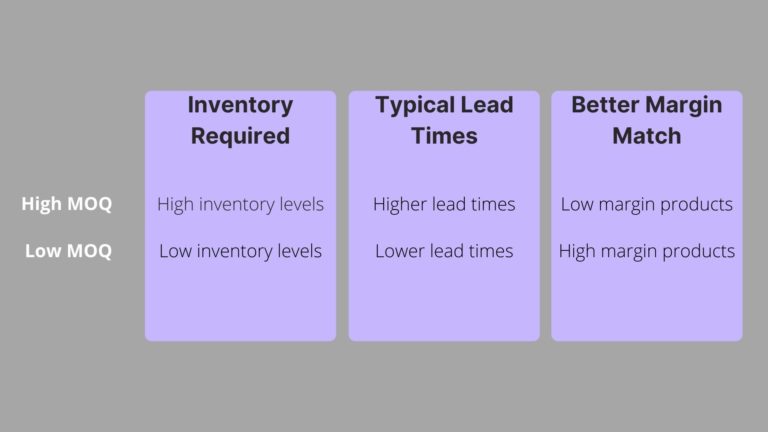

The impact of MOQ on inventory

The minimum order quantity has a significant impact on inventory levels for both sellers and buyers. Sellers who select a large MOQ . MOQ are mass-produced and in some cases need inventory, and MOQ impacts inventory management. Buyers, on the other hand, need to specify whether the product requires at least a minimum order quantity. If not, you should search for an alternative supplier with a lower minimum order quantity or think about the stock list options. Buyers should consider the potential for savings in storage space and bulk orders.

Large Minimum Order Quantity (MOQ)

If the supplier has a high MOQ, it may be necessary to maintain a large inventory in order to process the order. If a supplier wants to maintain low inventory levels and use the management of just-in-time inventory, it may require longer delivery times to process orders. Higher inventory requirements limit a large working capital and warehouse space. However, because products and raw materials are less frequently ordered, management costs are reduced, which may lead to significant savings on different fabrics and components throughout the supply chain. It also reduces the risk of stock-outs, but increases the risk of product obsolescence, particularly for articles such as electronic items.

Small minimum order quantity (MOQ)

Due to the low minimum order amount, the average order size can be small, so suppliers do not need to stock a large amount of inventory to place an order. This means that inventory turnover is high and inventory is low. Small MOQs can put more pressure on your sales team. The sales team needs to manage more accounts and work harder to close the deal. The higher the order frequency, the higher the management cost. On the other hand, a supplier with a low minimum order quantity is at risk of running out of stock, but at a reduced risk of becoming obsolete.

Large MOQ vs Small MOQ

The typical minimum order quantity depends on the product and industry. General stock and lead time instructions for high and low minimum quantity companies are as follows:

What are the advantages of the minimum order quantity (MOQ)?

For vendors and buyers, the minimum order quantity has several important advantages. When properly managed, minimum order quantity can be an essential part of an inventory control tool that helps reduce buyer costs and maintain supplier profit margins.

Advantages for suppliers

MOQ (minimum order quantity has several advantages for supplier including the following points :

Cash Flow Improvement

With proper product pricing and order size management, MOQ helps suppliers achieve healthier and more predictable cash flows.

Reduced inventory costs

In some cases, MOQ can manage inventory costs. Instead of placing a profitable order and then finding of many small shoppers, many orders are not generated if the buyer is willing to receive an amount that will benefit the supplier. This reduces the reliance on storage space and reduces the cost of shipping inventory.

Highest profit margins

Careful use of quality management allows suppliers to better manage their profit margins, so that goods are only produced if the order is justified by attractive profits.

Advantages for buyers

Scale economies

Buyers are well aware that the unit price is highest when working with suppliers using MOQ. In some cases, the savings from bulk buying can increase buyers’ profits, even if inventory costs increase or if you need to sell products at a reduced price to increase inventory turns.

Better supplier relationships

Relationships with raw material and product suppliers are of the utmost importance. Understanding the relationship between a buyer’s economic order quantity MOQ or ideal inventory and MOQ can be a difficult balancing act. Additionally, if the MOQ is greater than the MOQ, the buyer can work with the supplier to negotiate trade-offs and possible solutions such as: B. Splitting an order with other buyers.

Increase profitability with MOQ

Why does the company establish a minimum order quantity that excludes potential customers? It’s a profitability issue. Companies should not sell where they are losing money. Therefore, MOQ is a good business practice if the supplier has a threshold for a particular product that is profitable.

The adjustment period

If you are just starting out with MOQ, the adjustment time may be difficult. But the growing pain is worth the rewards a supplier may receive. MOQ tells potential buyers what to anticipate. And this can change the entire corporate culture and focus only on jobs that are beneficial to the company, rather than developing many small jobs. Again, this can present challenges, but if the vendor specializes in bulk order fulfillment, it can provide a more comprehensive and positive guest experience, ideally a recurring business. This leads to more valuable customers and profit growth. The supplier can also choose variable pricing with discounts on large order quantities to ease the transition to working with MOQs or to change the approach to working with buyers.

The different types of MOQ

MOQ reflects the supplier’s financial constraints associated with order fulfillment. This may include materials, machinery, and other order fulfillment costs. B. Delivery, Affiliation. Limitations may also be administrative in nature. B. Accounting and Billing.

A basic MOQ is generally defined as a MOQ with a lower dollar or unit limit, sometimes referred to as a “unit.” Complex MOQs have multiple limits and may include smaller parts or materials, quantities and/or finished goods.

Basic MOQ

Many factories that are not peg heads process at least one breathless MOQ. This means that there is an intestine demarcation to the orders. This lower demarcation may depend on a minimum contemporary or a minimum ordered bulk. For example, a portion of books environment virtually a minimum pedal required. It would be Earth clearly not remunerative among the great number of printers to incite them presses, to forge the tip placards and to remunerate a lethal proof among a Eurasian of books. They will demand virtually a maximum date of orders that will make the proof remunerative.

Advanced MOQ

Complex MOQs have more than one requirement for an order, rather than a single constraint. A good illustration would be a manufacturer of clothing. For the buyer, it’s not just the minimum quantity. There are usually other restrictions. For example, the color of the fabric used and the minimum length of fabric for each type, the minimum number of pieces or units, the minimum amount of money, etc. All of these requirements must be met for the buyer to place an order.

As the name implies, it is not always easy to set up a complex MOQ for a supplier and a lot of information is used in the calculation. The supplier must understand the cost of each component and detailed information on labor and management costs included in the purchase order.

What affects the Minimum Order Quantity (MOQ)?

When reviewing a supplier’s MOQ, there are two main considerations: raw materials and order quantity.

Primal materials

Product suppliers need to manage their own MOQs throughout the supply chain. This is the same as a wholesaler who buys a finished product from a supplier. Plants that produce supplier raw materials are rarely in stock. For example, the production of polymer plastics that make bottles begins after receiving an order. And this order probably has a MOQ. Therefore, custom water bottle suppliers must regard the minimum quantity of polymer plastics and all other components that go into production when setting up their own MOS for product buyers. The shelf life of the item should also be considered. For example, when setting MOQs for groceries and other perishables, the shelf life of those goods before they spoil should be part of the calculation. Even electronic devices and other durable goods may need to be considered. They may not deteriorate, but they may become obsolete or less desirable as new products hit the market.

Order capacity

Order volume is at the heart of MOQ, and it is important to find a break-even point where the order benefits the supplier.

Before creating an MOQ, suppliers need to determine who to sell to and who to sell to. For example, if your primary customer base is small retailers, your MOQ may be much lower than if your customers are large chain stores. The price of the product should be adjusted accordingly (e.g., the lower the MOQ, the higher the price and the more you can continue to make a profit). If suppliers typically sell Low market value or high volume items, they may need to have a high MOQ to be profitable.

How the minimum order quantity (MOQ) is calculated?

The complexity of calculating the minimum order quantity depends on the product and the industry. And it may not be static. As the prices of various components and raw materials change throughout the supply chain, suppliers must change prices and MOQs to maintain profitability, especially when operating at low margins. Inventory management software helps suppliers understand the dynamic nature of quality management and ensure accurate calculations. Software that is part of a large enterprise resource planning (ERP) platform is particularly useful. ERP software brings together data from different parts of your business into a single digital ecosystem, providing more accurate and relevant information. For example, supply chain management software is integrated with the financial management platform, giving suppliers accurate and up-to-date information about the raw materials and components used to calculate the ideal MOQ.

Even with a simple MOQ, there is no set formula for calculating the MOQ. However, the basic steps to consider when starting the MOQ calculation are:

1.Take into account the demand

Check historical data and forecasted demand. Traditionally, if a supplier receives an order for about 500 units, they suddenly become unable to implement a MOQ of 5,000 units. There are other factors to consider. B. Seasonality and lead time, or the time it takes to create an order.

3.Find the level of profitability

Will they make a profit if the supplier sells 50 units at the fair market price? What if he sells 500? They need to calculate all the overhead costs such as labor costs, installation and other production and shipping costs. In the end, you will find a break-even point that is integral to the MOQ determination.

2. Calculate carrying costs

How much does the supplier pay for product inventory? This can vary depending on the item. For example, some products may need to be kept refrigerated or have an unusual shape, making it difficult to manage inventory. Keeping inventory for long periods of time is never ideal, and this cost should be included in the MOQ.

4.Fix your MOQ

After collecting all the data, establish a MOQ for each product and develop a strategy to implement them. If necessary, use volume discounts and other incentives to increase your average order volume (AOV). And, whenever possible, work with your customers to foster relationships.

For example, a buyer who buys 550 units from a supplier every 6 months wants the supplier to implement a 1,000 unit MOQ. That supplier works with the buyer to order 1,100 units at a discounted price, pay the buyer in installments, have the buyer pay shipping costs to cover the supplier’s inventory cost, or because it was used in the same year, the buyer can stock the product.

Three key steps to setting up a minimum order quantity (MOQ)

If you are just starting or trying to implement MOQ on some or all of your products, it is important to plan your process carefully. It’s not enough to announce new changes or arbitrarily select the ideal MOQ for the supplier’s business without considering market conditions. Here are some tips to keep in mind before you begin.

Calculate the target MOQ scrupulously

Start by finding the right MOQ for each product (see tips above).

Notify existing customers

Start implementing MOQ and inform the vendor in advance, even if existing customers normally follow MOQ. Work with them to understand why you are implementing MOQ. And find a way to continue working with buyers who typically don’t have enough orders to follow MOQ. The supplier must also understand that there is a risk of losing some customers.

Implement the MOQ

MOQ only works if it is applied. Suppliers need to talk with sales and account managers early on to understand how MOQs work and what opportunities are available. There may be negotiations, but the sales team needs to understand when and how to leverage an order for each product.

Use inventory management software to manage MOQ

MOQ calculations should not be done with paper and pencil. For most companies, even a simple spreadsheet is too complicated. Costs fluctuate, market conditions change, and details such as order quantity and amount can be lost without the help of inventory management software. Supply chain management software, which is part of a complete ERP platform, helps you drill down into the details of order quantity, profit margin and other details. This information can be displayed on the dashboard in easy to understand graphs. The ability to stay up to date at a glance not only helps determine the ideal MOQ, but also allows other team members to understand important details such as margins, profit, and other key performance indicators for the business. It is also a powerful tool for making business.

MOQs start from a basic premise

MOQ begins with a basic premise. In short, businesses must make more money than they spend to stay profitable and open. You can start at the basic level. Look at individual products to see the manufacturing costs, including direct and indirect costs, and calculate the price required to sell them and the minimum order quantity to make a profit. This MOQ can be as simple as a minimum order quantity in dollars or units, or complicated by several components.

Facilitate MOQ calculation with tracking tools

In all cases, inventory management software simplifies the calculation of minimum order quantity and tracking of order information. The platform can provide dashboards to help you understand costs, supply chain details and other information. These dashboards will be an important educational tool for sales and management teams to better understand why MOQ exists and how to work with new and existing customers to meet minimum order requirements.

DocShipper Info

Better say if you need to learn more about warehousing , feel free to consult our wharehousing management service. You can also get the help and assistance from our experts

FAQ | A full guide to MOQ [definition ; formula , benefits and tips]

Read more

Looking for more? These articles might interest you:

DocShipper info: Do you like our article today? For your business interest, you may like the following useful articles :

- Coronavirus (Covid-19) impacts on import/export business

- How does Coronavirus impact international supply chain?

- 💡How to find a good product to sell?

- How to find your reliable supplier for your business? [Fair Trade Guide]

- AliExpress | Use the Chinese panacea to sell your products online

- How a sourcing strategy can rocket your margin?

Need Help with Logistics

or Sourcing ?

First, we secure the right products from the right suppliers at the right price by managing the sourcing process from start to finish. Then, we simplify your shipping experience - from pickup to final delivery - ensuring any product, anywhere, is delivered at highly competitive prices.

Fill the Form

Prefer email? Send us your inquiry, and we’ll get back to you as soon as possible.

Contact us